While the criteria for judging a “great car” evolve with the times, “great to drive” and “great to sit in” remain core demands. In 2025, as Mercedes-Benz celebrates the 20th anniversary of its R&D and production in China, it takes the “Mercedes-Benz Standard” Tech Day as an opportunity to comprehensively reveal how it crafts luxury vehicles that meet global Mercedes-Benz standards while precisely catering to the needs of Chinese customers. This is achieved through world-leading chassis technology, supremely comfortable seating engineering, and localized innovations deeply rooted in the Chinese market.

Chassis: From “Golden Standard” to “China Formula,” The Art of Balancing Tech and Sensation

As the core of automotive handling, the chassis epitomizes 139 years of Mercedes-Benz engineering heritage. Based on insights into global user needs and a deep understanding of Chinese road scenarios, Mercedes-Benz has built a chassis development system “rooted globally, focused on China,” quantifying the complex driving experience into measurable scientific standards.

The “Mercedes-Benz Driving Control Golden Standard” is central to this system: over 1,000 component indicators are distilled into 130+ objective KPIs. Using 40 sensors covering 100+ measurement directions, it ultimately focuses on five dimensions: ride comfort, safety feel, sense of control, sportiness, and precision. Every production car must be a “five-dimensional warrior,” achieving benchmark industry levels, especially in comfort, safety feel, and sense of control. Beyond this, subjective evaluation engineers, dubbed “golden butts,” provide holistic oversight based on human perception, ensuring alignment between data and real-world experience.

The “Mercedes-Benz Driving Control Golden Standard” is central to this system: over 1,000 component indicators are distilled into 130+ objective KPIs. Using 40 sensors covering 100+ measurement directions, it ultimately focuses on five dimensions: ride comfort, safety feel, sense of control, sportiness, and precision. Every production car must be a “five-dimensional warrior,” achieving benchmark industry levels, especially in comfort, safety feel, and sense of control. Beyond this, subjective evaluation engineers, dubbed “golden butts,” provide holistic oversight based on human perception, ensuring alignment between data and real-world experience.

To suit the diverse scenarios of Chinese users, Mercedes-Benz offers a “Chassis Haute Couture” solution: over 10 suspension styles (Comfort, Sport, Off-Road, etc.) precisely match high-frequency usage scenarios. The unique “Agility Control System” enables steel suspensions to deliver an “air suspension-like” experience – initial suppleness absorbs vibrations on bumpy roads, while mid-to-late firmness provides solid body support. The Adaptive Damping System Plus (ADS+) can independently adjust the damping of each wheel, responding to road conditions thousands of times per second. Exclusive tuning of hydraulic bushings reduces speed bump impact peaks by one-third, delivering a “buttery smooth” quality.

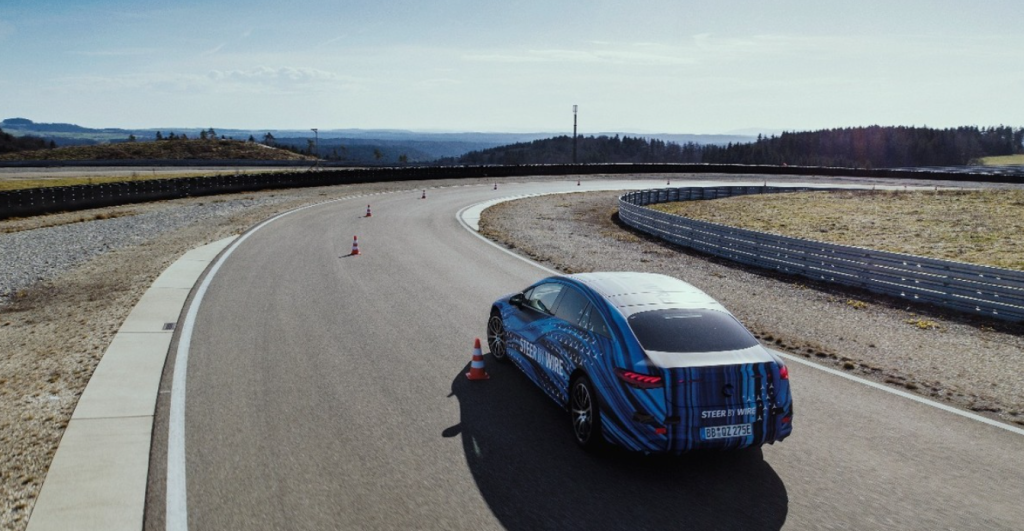

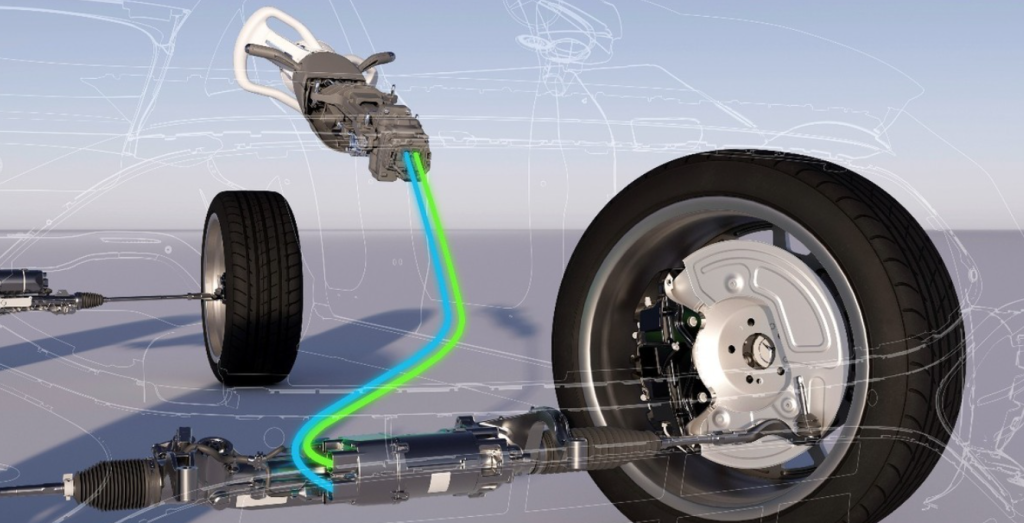

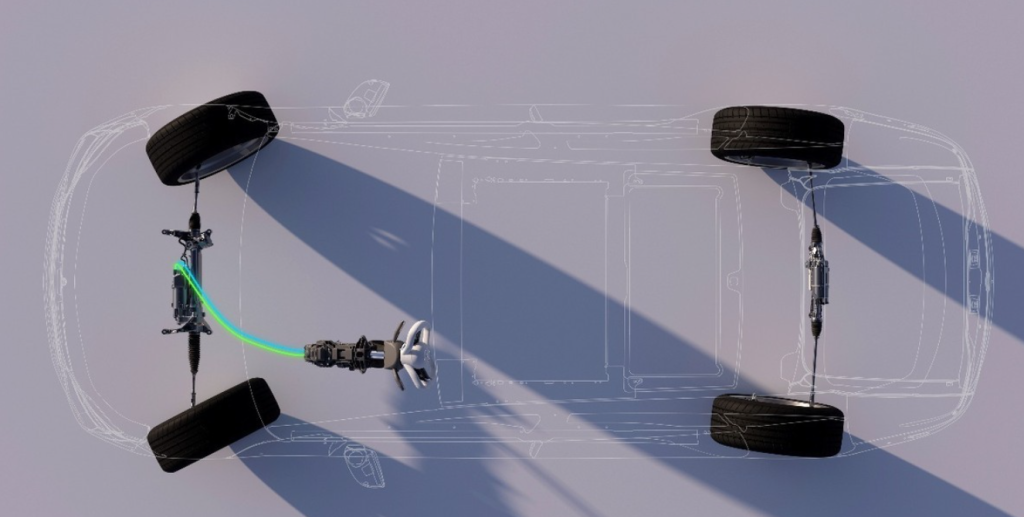

In the R&D process, Mercedes-Benz adheres strictly to “not a minute nor a step can be skipped”: from CAD design and digital simulation to real-world testing, it undergoes 4 years of refinement. This includes extreme tests from -40°C to 70°C, emergency braking at speeds up to 200 km/h, and 1.1 million kilometers of testing on Chinese roads alone. The application of steer-by-wire technology breaks mechanical limitations, offering agility at low speeds and stability at high speeds. Combined with rear-wheel steering, it gives large luxury cars the maneuverability of compact models, laying the groundwork for Level 3 autonomous driving.

Seats: 1,460 Days of Refinement, 6,000+ Standards, Redefining the True Meaning of “Sitting in a Mercedes”

Behind the reputation of “Sitting in a Mercedes” lies the ultimate pursuit of comfort, safety, and durability. Mercedes-Benz seat development spans 1,460 days, encompassing 6,000+ control standards. Every detail, from the skeleton to the upholstery, from function to safety, undergoes rigorous refinement.

- Safety is the Baseline: Proprietary skeleton platforms meet the world’s strictest safety standards. Full-skeleton electrophoretic anti-corrosion ensures 15 years of reliability. The S-Class features 18 airbags, including the unique PRE-SAFE® Impulse Side system which moves occupants away from the impact zone before a collision. The world’s first rear-seat frontal airbag adds comprehensive protection. In over 200 safety tests, seats must withstand a 20g acceleration within 20 milliseconds in rear impacts. Headrests are impacted at 25.1 km/h against 10 weak points, exceeding industry standards.

- Comfort is the Experience: The E-Class features 0.84 square meters of heating pads covering side bolsters and headrests. The S-Class uses 39 meters of heating wire with thermal mapping to eliminate “hot spots.” Ventilation, using 4-5 fans, achieves airflow of 9 liters/second with noise controlled below 40 decibels – comparable to a computer fan. The pioneering hot stone massage function (introduced 2014) undergoes -40°C to 80°C and 1,480 hours of durability testing, balancing comfort and longevity. Ergonomics certified by the German Back Health Association (AGR) ensure comfort even during long journeys.

- Quality & Durability: Nappa leather meeting Mercedes-Benz standards undergoes double inspection, retaining its natural feel with vegetable tanning. An S-Class seat uses 58 leather pieces cut by a 2,000-bar high-pressure water jet, with 16,000 needles creating precise perforations and nearly 40,000 stitches, with a seam tolerance under 5mm. Endurance testing includes 40,000 ingress/egress cycles (15,000 verified by humans), equivalent to 18 years of daily use. The story of a Greek taxi driver covering 4.6 million kilometers in a Mercedes 240 D over 30 years stands as the ultimate testament to its durability.

20 Years in China: “Where We R&D is Where We Produce”

Over the past 20 years, Mercedes-Benz has realized “where we R&D is where we produce” in China: Beijing Benz has become one of the world’s largest and most advanced manufacturing bases, with cumulative production exceeding 5 million units. Its China R&D network forms a Beijing-Shanghai “twin-engine” – Beijing focuses on e-mobility and whole-vehicle testing, while Shanghai specializes in intelligent connectivity and autonomous driving. This setup enables “China speed,” launching systems like Highway Pilot Assist (12 months from concept to market) and the next-gen rear-seat entertainment system (18-month development cycle), while also feeding innovations back to the global network.

On the production front, Beijing Benz centers on “Digitalization, Flexibility, Efficiency, Sustainability”: The MO360 system boosts efficiency by 15%. Flexible production lines enable mixed combustion and electric vehicle assembly. Body shop automation reaches 100%, with welding precision at 0.1mm. The use of 210,000 square meters of photovoltaic panels, alongside AI and digital twin technologies, sets a new benchmark for high-end manufacturing.

Conclusion: Standards Define True Luxury

From the chassis’s “Golden Standard” to the seat’s “10,000 Controls,” from the 4-year R&D cycle to 20 years of localization, Mercedes-Benz uses “Standards” to prove that true luxury is not momentary dazzle, but safety, comfort, and reliability tested by time. As Mercedes-Benz consistently upholds: Crafting luxury through “Standards,” empowering experience with “Technology,” to build truly great cars for Chinese users – cars that are “Great to Drive” and “Great to Sit In.”